Oct 10,2023

In the ever-evolving world of automotive manufacturing, precision, durability, and cost-effectiveness are paramount. To meet these demands, the industry relies on various manufacturing processes, with die casting emerging as a crucial method for producing high-quality automobile parts.

In this blog post, we will explore the fascinating world of die casting, its applications in crafting key automotive components, the materials used, and the importance of custom die casting to meet unique needs.

Die casting is a manufacturing process that involves injecting molten metal into a mold, typically made of steel, under high pressure. Once the metal solidifies, it is removed from the mold, resulting in a highly accurate and detailed part. This process is known for its precision and is used extensively in the automotive industry.

Die casting allows for intricate designs and tight tolerances, ensuring parts fit perfectly within the automobile assembly.

The efficiency of the die casting process leads to reduced material waste and lower labor costs, making it an economically viable option.

Die casting offers a rapid production cycle, which is crucial in the fast-paced automotive industry.

Manufacturers can achieve complex geometries and detailed features, enhancing both aesthetics and functionality.

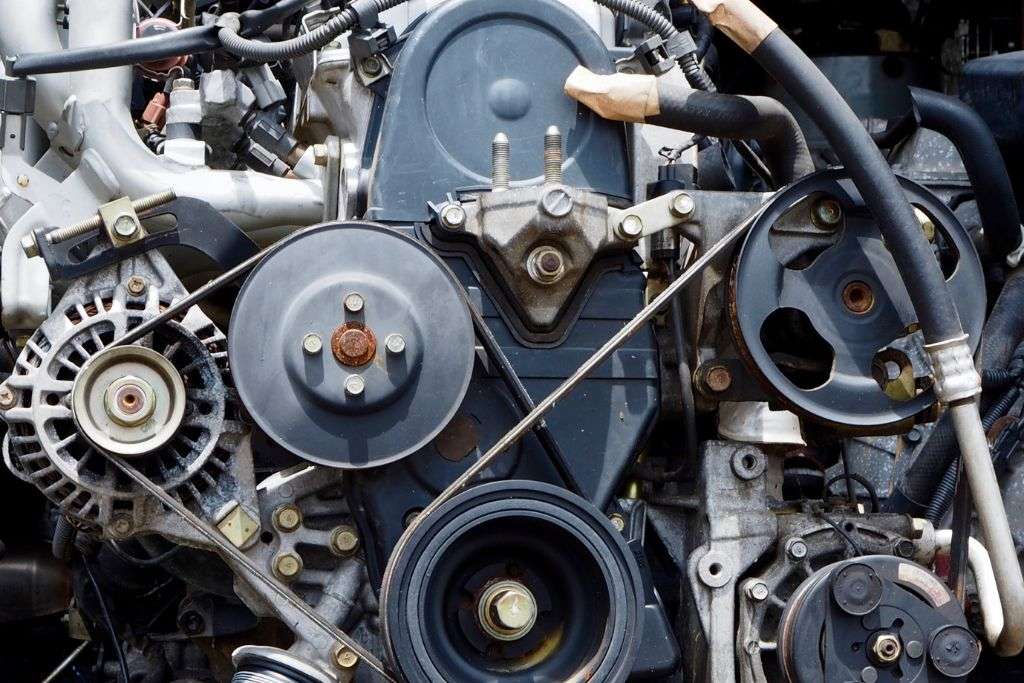

Die casting is employed to craft a wide array of automobile components, contributing to the overall performance, safety, and aesthetics of vehicles. Let's explore some of the key parts manufactured using this method:

These vital engine components require high precision to ensure efficient combustion. Die casting guarantees consistent quality.

The heart of the engine, these complex parts demand the durability and intricate detail that die casting provides.

Ensuring proper lubrication, oil pans must be leak-free and structurally sound, making die casting an ideal choice.

Transmission Cases: Housing the gears and ensuring smooth gear shifts. Transmission cases need to be strong and heat-resistant, qualities offered by die casting.

Precision is crucial in gearboxes, and die casting helps maintain the necessary tolerances for optimal performance.

These critical components demand high strength and precise geometry to ensure safe and responsive steering.

Supporting the suspension system, control arms benefit from the lightweight yet robust nature of die-cast parts.

Numerous brackets throughout the vehicle, from exhaust mounts to sensor housings, rely on die casting for their production.

Lightweight and durable, die-cast aluminum wheels are a popular choice among manufacturers and car enthusiasts alike.

Combining aesthetics and functionality, die-cast door handles offer durability and intricate designs.

Front grilles, often a vehicle's signature feature, require fine detailing that die casting effortlessly provides.

From air vent covers to multimedia bezels, die casting ensures that interior components are both visually appealing and functional.

Die casting materials play a crucial role in the quality and performance of automobile parts. Here are some commonly used materials and their advantages:

Aluminum is significantly lighter than other metals, contributing to fuel efficiency.

Aluminum parts are less susceptible to rust, enhancing longevity.

Ideal for parts that manage heat, such as cylinder heads.

High Precision

Zinc's low melting point allows for intricate detailing and thin-walled parts.

Cost-Effective

Zinc is abundant and easy to recycle, making it an economical choice.

Good Surface Finish

Zinc parts often require minimal post-processing, saving time and resources.

Characteristics of Magnesium Die Casting

Exceptional Lightweight

Magnesium is the lightest of all structural metals, reducing vehicle weight.

High Strength-to-Weight Ratio

Ideal for applications where strength and weight are critical.

Electromagnetic Shielding

Magnesium parts can offer electromagnetic interference (EMI) shielding properties.

The choice of material depends on the specific requirements of each automobile part. While aluminum is common for engine components due to its lightweight and thermal properties, zinc may be favored for intricate interior details. Magnesium, with its lightweight strength, is gaining popularity in various applications.

Custom die casting is a vital aspect of automobile part manufacturing. Here's why it matters:

When standard parts won't suffice, custom die casting steps in to meet unique needs. Whether it's crafting a one-of-a-kind component for a concept car or creating a specialized part for a high-performance vehicle, custom die casting offers unparalleled flexibility.

To illustrate the significance of custom die casting, let's look at a few real-world examples:

Manufacturers often need custom parts for concept cars, where design innovation is at its peak. Die casting allows for the creation of unique, eye-catching components that capture the essence of the vehicle.

High-performance cars require components that can withstand extreme conditions. Custom die casting ensures these parts meet the stringent demands of racing and sports cars.

As the automotive industry shifts towards electric vehicles, custom die casting plays a vital role in creating lightweight and efficient components to maximize range and efficiency.

Ensuring the quality and reliability of automobile parts is paramount. Die casting manufacturers employ various methods to achieve this:

Inspection During the Die Casting Process

Regular inspections of molds and the casting process itself help identify and rectify issues before they affect the final product.

Techniques such as X-ray and ultrasound are used to detect internal defects without damaging the part.

Meeting industry-specific standards and regulations is essential to guarantee the safety and performance of automobile parts. Die casting manufacturers must adhere to guidelines related to materials, design, and testing.

The automotive industry is increasingly focusing on sustainability, and die casting has its own eco-friendly advantages:

Recycling and Reuse of Materials

Die casting materials like aluminum and zinc are highly recyclable, reducing waste and conserving resources.

The efficiency of the die casting process translates into lower energy consumption compared to alternative manufacturing methods.

Researchers and manufacturers are continually exploring ways to make die casting even more sustainable, such as using recycled materials and improving energy efficiency.

The future of die casting in the automotive industry holds exciting possibilities:

Innovations in die casting equipment, such as improved control systems and automation, will enhance production efficiency and product quality.

Artificial intelligence and automation will play a more prominent role in die casting, enabling predictive maintenance, real-time quality control, and increased process optimization.

The development of new materials and techniques, such as metal-matrix composites and additive manufacturing, will expand the possibilities for die casting in automotive applications.

Die casting is an indispensable method for manufacturing automobile parts that meet the rigorous demands of the automotive industry. From engine components to interior details, this process ensures precision, durability, and cost-effectiveness.

As the industry continues to evolve, custom die casting, sustainability, and emerging technologies will shape the future of automotive manufacturing, providing even more innovative and high-quality solutions for vehicles on the road. Whether it's aluminum, zinc, or magnesium, die casting remains a cornerstone of modern automotive production, driving the industry forward.